Every Board Held to Standards

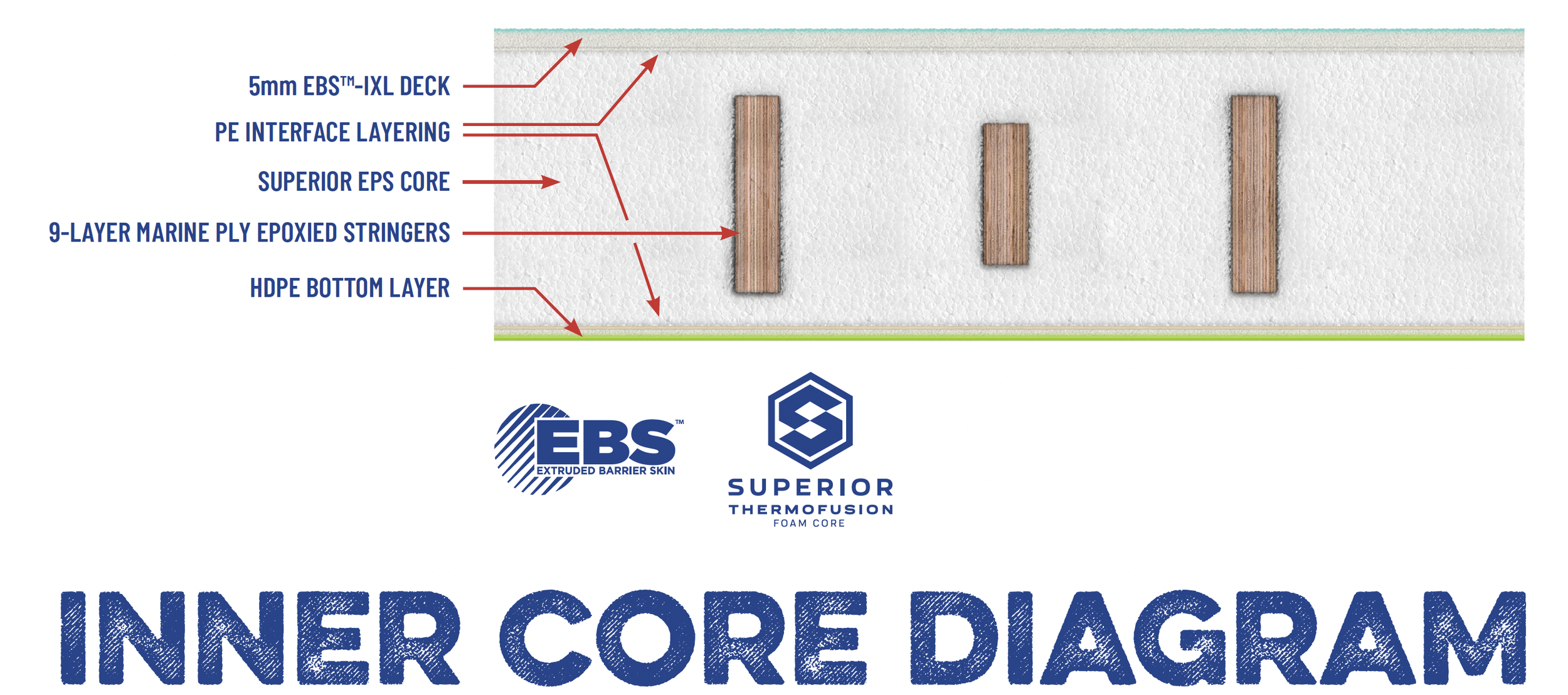

SUPERIOR EPS CORE

Our proprietary expanded polystyrene core features a mixture of polymers that surpass other basic foam suppliers. Maintaining optimal purity and cleanliness during the process creates a lively performance.

PE INTERFACE LAYERING

Between both deck and bottom shell layering lies the perfect interface that creates the perfect bond and enhances rigidity. Our interface allows us to not use any harmful glues or otherwise at the core of construction.

MARINE-PLY STRINGERS

Quality layered wood is shaped to the unique rocker of each mold unlike most of our competition. Each stringer is hand laminated with a nanotechnology epoxy that is CARB compliant and creates better bond to core.

TEXTURED EBS™-IXL TOP DECK

Our proprietary elastomer topped deck over IXL is a patented process that creates more rigidity and still maintains the perfect amount of softness for safety and comfort. Textured grip can be used without wax.

HIGH DENSITY BOTTOM SKIN

High tensile strength polyethylene bottom maintains the perfect recoil and balance of rigidity for any foam surf-craft. Our HDPE is crafted in house. Any trimming on yield is recycled into our other components.

THERMAL INDUCTION PHASING

Every board is set in our heat-induced environment to assist is checking lamination bonds and making sure boards are well set against bubbles. The environment mimics a heat soaked car or garage for assurance.

Download our full catalog Here